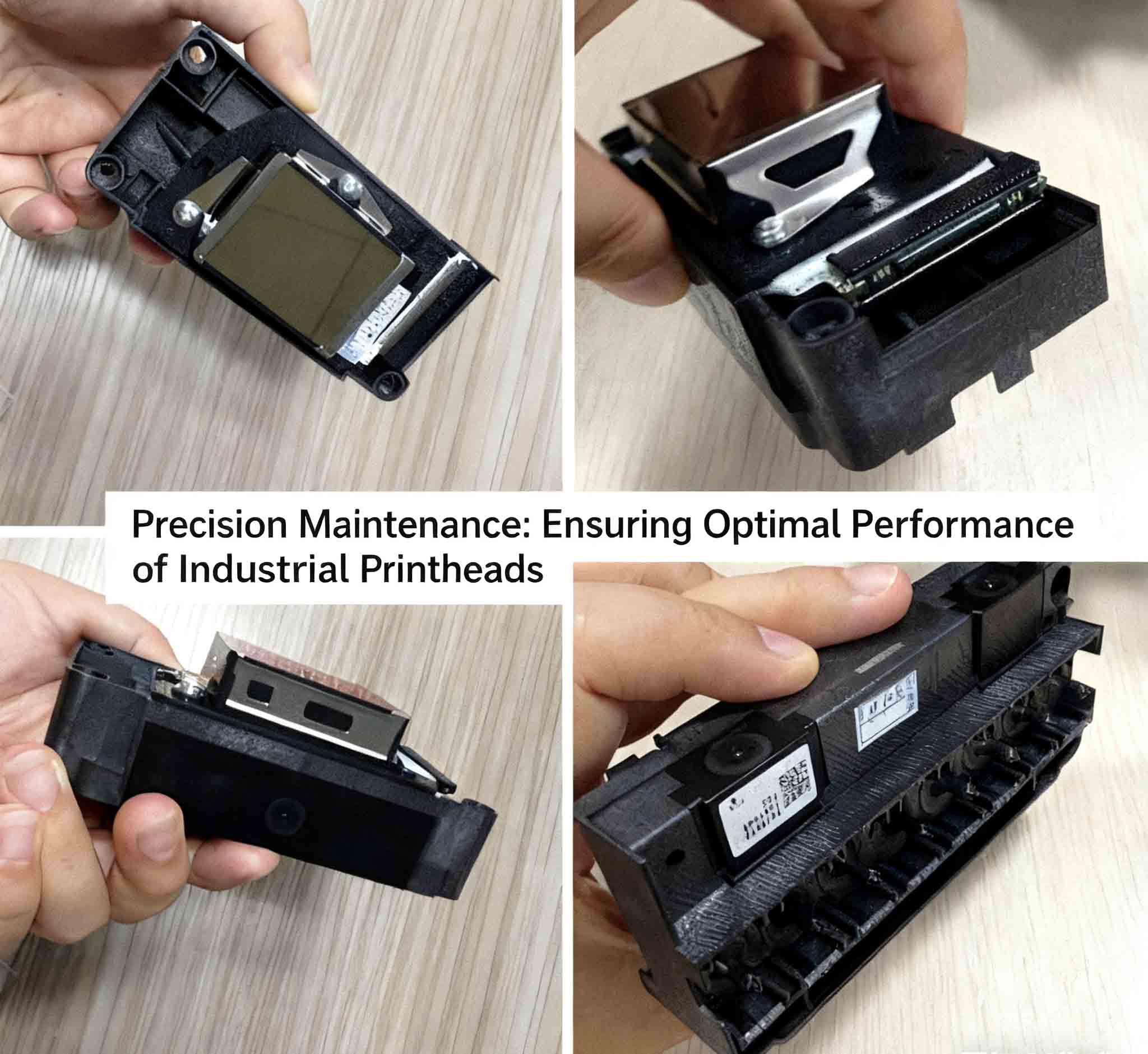

Printhead Maintenance Best Practices: A Technical Guide for Industrial Inkjet Systems

A technical guide to printhead maintenance for industrial inkjet systems. Covers daily, weekly, and industrial-scale protocols for Epson, Konica, and other piezoelectric printheads.

For educational purposes only — Always consult the official manufacturer documentation before performing maintenance.

Introduction: Why Maintenance Matters in Industrial Printing

In high-speed, high-duty-cycle industrial inkjet systems, printhead reliability directly impacts uptime, print quality, and total cost of operation. While printheads such as the Epson DX5, Konica Minolta XP600, or Polaris 512 are engineered for durability, their performance depends heavily on proper maintenance.

This guide outlines industry-recognized best practices for maintaining piezoelectric printheads in production environments. It is based on publicly available technical documentation, field reports, and standard operating procedures used in packaging, textile, and décor printing industries.

⚠️ Note: This article is for educational purposes only. Always consult the official manufacturer documentation before performing maintenance.

1. Daily Maintenance Protocols

Routine daily checks prevent minor issues from escalating into costly downtime.

Nozzle Plate Cleaning

- Use isopropyl alcohol (IPA, 90%+ purity) and lint-free swabs or wipes to gently clean the nozzle plate.

- Avoid direct contact with piezo elements or electrical contacts.

- Do not use cotton swabs — fibers can clog nozzles.

- Clean immediately after ink spills or splashes.

✅ Source: Epson Maintenance Guidelines for DX Series Printheads

Ink Recirculation System Check

- Ensure ink is actively circulating to prevent stagnation and viscosity changes.

- Verify that the ink supply lines are free of bubbles or blockages.

- For UV inks, confirm that the heating system maintains ink at optimal temperature (typically 30–35°C).

Environmental Monitoring

- Maintain ambient temperature between 25–30°C.

- Keep relative humidity at 40–60% RH to prevent ink drying or condensation.

- Use air filtration (e.g., HEPA) in print rooms to reduce airborne particles that can clog nozzles.

2. Weekly & Monthly Maintenance Procedures

Ultrasonic Cleaning (Weekly)

- For heavily used systems, perform ultrasonic cleaning during scheduled downtime.

- Use a 40kHz ultrasonic bath with IPA or manufacturer-recommended fluid.

- Duration: 15–30 minutes, depending on ink type and contamination level.

- After cleaning, allow full drying before reinstallation.

✅ Common practice in third-party service centers and OEM maintenance protocols

Signal and Electrical Integrity Check

- Inspect LVDS cables and connectors for wear, bending, or oxidation.

- Loose or damaged cables can cause misfiring, data loss, or printhead communication failure.

- Power down the system before disconnecting any components.

Firmware and Driver Verification

- Check for firmware updates from the printhead or printer manufacturer.

- Some updates improve droplet control, reduce misfires, or enhance compatibility with new ink types.

3. Troubleshooting Common Issues

| Symptom | Likely Cause | Recommended Action |

|---|

| Missing nozzles | Partial clog, weak firing, or signal issue | Run nozzle check → Perform cleaning cycle → Re-test |

| Horizontal banding | Misalignment, inconsistent ink flow | Realign printhead → Check ink pressure → Clean dampers |

| Inconsistent density | Nozzle wear, ink viscosity drift | Measure drop weight (if possible) → Replace if degraded |

| Complete failure | Electrical fault, physical damage | Power cycle → Check connections → Contact OEM for diagnostics |

📌 Tip: Log nozzle check results weekly to detect degradation trends early.

4. Industrial-Scale Maintenance Practices

For 24/7 production environments, maintenance must be systematic and data-driven.

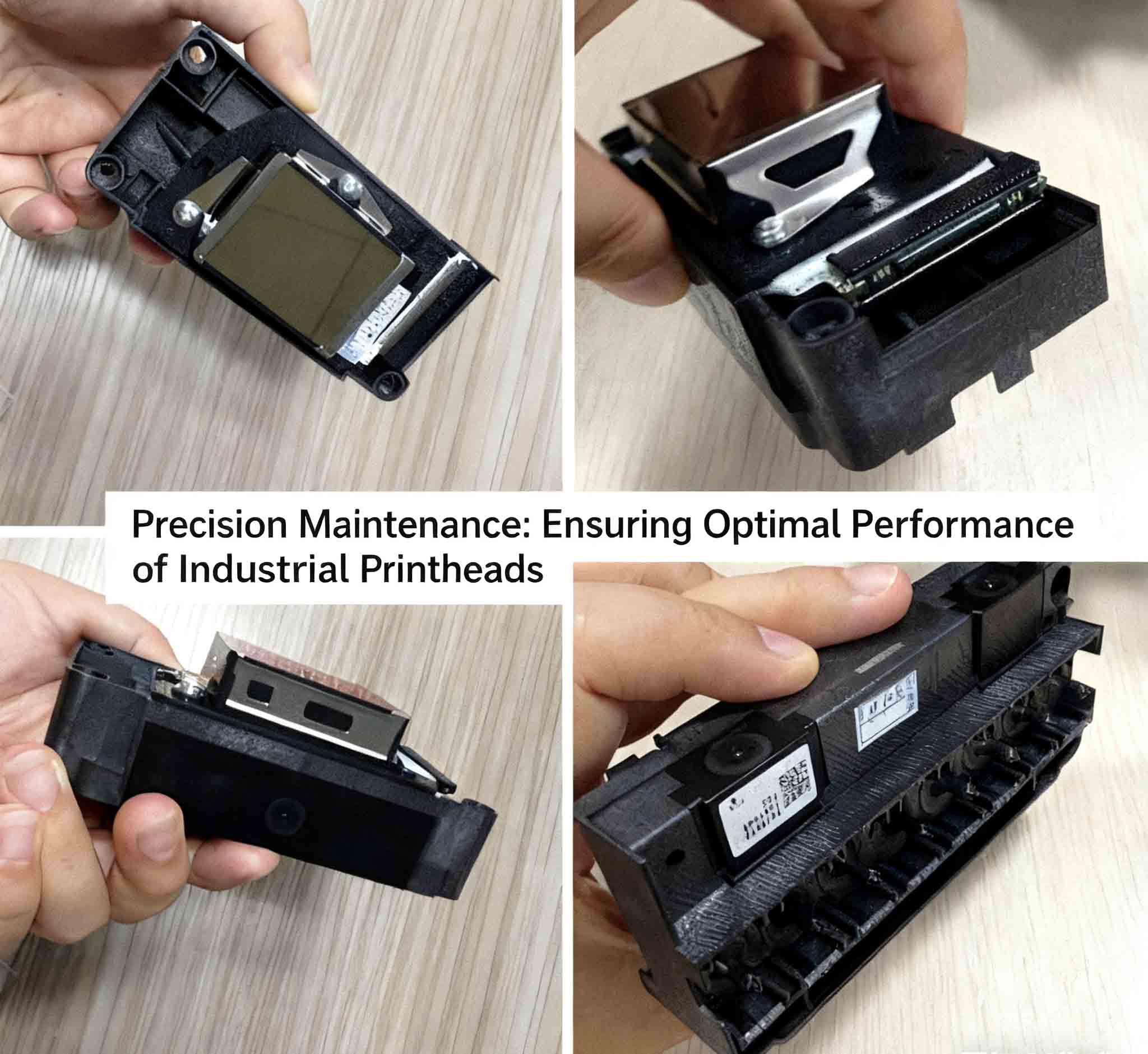

Scheduled Downtime Cleaning

- Plan deep cleaning during planned maintenance windows.

- Remove printheads carefully and store in sealed containers with protective caps.

Nozzle Health Monitoring

- Use automated nozzle checking software (if available).

- Generate weekly reports to track performance over time.

Ink Viscosity Control

- Use inline viscometers for real-time monitoring.

- Target range: 10–12 cP for UV ink, 3–5 cP for water-based (varies by model).

Environmental Control

- Install climate control systems in print rooms.

- Monitor particulate levels — dust is a leading cause of nozzle clogging.

5. Manufacturer Recommendations (Publicly Available)

Epson (from DX Series Documentation)

- ✅ Use only IPA or manufacturer-approved cleaning fluids.

- ❌ Never use acetone, MEK, or strong solvents — they can damage seals and piezo actuators.

- ❌ Do not touch the nozzle plate with hard objects.

- ✅ Always power down before disconnecting cables.

General Industry Standards

- Avoid rapid temperature changes.

- Store unused printheads in sealed bags with moistened cleaning pads (if specified).

- Label all components during disassembly to avoid misinstallation.

Conclusion

Effective printhead maintenance is a combination of discipline, environment control, and adherence to technical protocols. While this guide compiles widely accepted practices, it does not replace official manufacturer procedures.

Always consult the official manufacturer documentation before performing maintenance. This guide is for educational purposes only.